Unlocking the Potential of 3D Printing Technology

Among the rapidly changing field of contemporary manufacturing, 3D Printing technology is a game-changer. 3D Printing, sometimes referred to as additive manufacturing in technical parlance, is transforming the design, prototyping, and production of goods. The possibilities of 3D printing technology are enormous and are growing, ranging from quick prototyping to producing intricate geometries that were previously unattainable. We will examine the amazing potential of 3D printing, as well as its advantages and innovative contributions to the manufacturing sector, in this blog article.

An Introduction to 3D Printing Technology

Using digital files as a starting point, 3D Printing technology builds three-dimensional items layer by layer. This process is known as additive manufacturing because it constructs objects by adding material instead of removing it as in conventional subtractive manufacturing techniques.

Material Innovations: Sustainability and Performance

Material innovation remains at the forefront of AM research, with recent developments focusing on both high-performance and sustainable materials. The quest for sustainability in Additive Manufacturing has led to the exploration of biodegradable and recyclable polymers, which can significantly reduce the environmental impact of AM processes (Chyr & DeSimone, 2023). Additionally, advancements in metal AM, particularly with new alloys and composites, are providing enhanced properties such as higher strength-to-weight ratios and better thermal resistance. These materials are crucial for applications in harsh environments, such as in space or deep-sea exploration (Vafadar et al., 2021).

Technological Advancements: AI and Automation

Among the crucial actions in 3D printing are:

Designing the Model:

Engineers and designers use CAD (Computer-Aided Design) software to generate intricate 3D models of the product that will be printed.

Getting the File Ready:

The digital model is transformed into an STL file, typically readable by the 3D printer. Following that, this file is divided into thin, horizontal layers.

Producing the Object:

After reading the sliced file, the 3D printer begins producing the object in layers utilizing a variety of materials, including metals, resins, and plastics.

Post-Processing:

To obtain the required qualities and appearance, the object may go through extra steps like cleaning, curing, or finishing once printing is finished.

Designing the Model:

Engineers and designers use CAD (Computer-Aided Design) software to generate intricate 3D models of the product that will be printed.

Technology Benefits of 3D Printing

Fast Prototyping: The capacity of 3D printing technology to generate prototypes rapidly is one of its most important benefits. Compared to traditional approaches, this rapid prototyping capabilities saves designers time and money by enabling them to test and modify their ideas more quickly.

complicated Geometries:

With 3D printing, it is feasible to create complicated geometries that are hard or impossible to do with traditional production methods. This talent is especially helpful in sectors that frequently need complex designs, including aerospace and healthcare.

Customisation and Personalization:

High degrees of personalization and customisation are possible with additive manufacturing. Customized products can be made to fulfill the needs of individual customers, which makes them perfect for manufacturing industrial components, bespoke goods, and medical implants.

Material Efficiency:

3D printing employs only the material required to make the object, as opposed to subtractive manufacturing, which frequently produces significant material waste. This effectiveness can result in cost savings and waste reduction, particularly when using pricey materials.

Flexibility and creativity:

By giving engineers and designers the latitude to try out novel ideas and designs, 3D printing promotes creativity. The development process can be accelerated through quick iterations and alterations made possible by the flexibility of additive manufacturing.

Utilizing 3D Printing Technologies

Healthcare:

Custom prosthesis, implants, and surgical guides are made possible via 3D printing. It is also essential for bioprinting, which is the process of printing living cells to make organs and tissues for study in medicine and possible transplants.

Aerospace and Defense:

3D printing technology helps the aerospace and defense industries produce intricate, lightweight parts that adhere to strict performance standards. Parts with complex interior structures can be produced via additive manufacturing, which reduces weight without sacrificing strength.

Automotive:

3D printing technology is used in the automotive industry for end-use part production, tooling, and prototype. Costs and development cycles are decreased by the speed at which custom components, like engine parts and interior trim, may be produced and tested.

Consumer Goods:

The ability to produce individualized and customized products thanks to 3D printing is revolutionizing the consumer goods industry. Additive manufacturing enables fast production and distinctive designs in a variety of industries, including electronics, jewelry, and fashion.

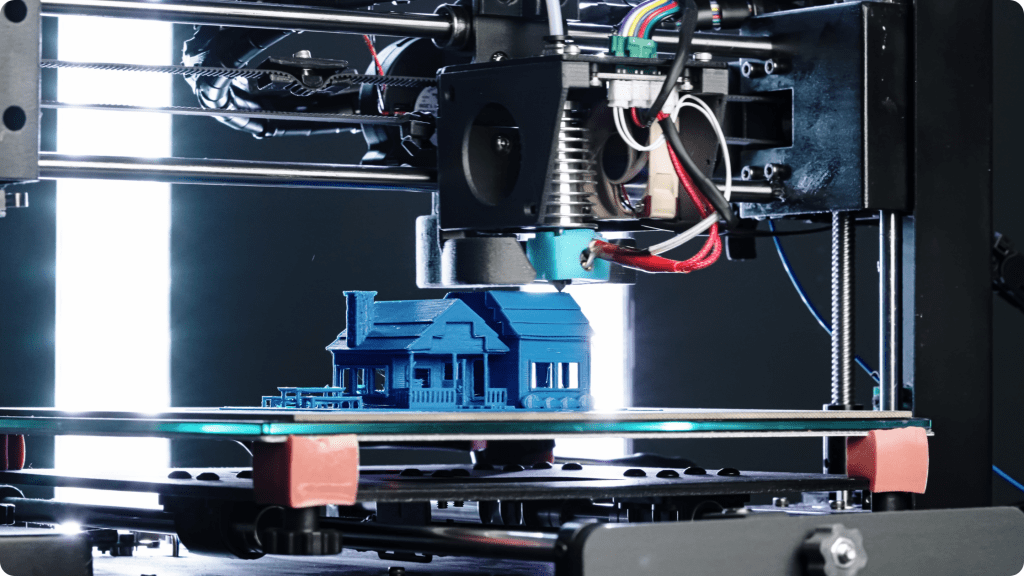

Architecture and construction:

Scale models, intricate building components, and even complete structures are produced using 3D printing technology in these fields. This method saves waste and time during construction while improving design flexibility.

The Technology of 3D Printing’s Future

The potential uses and advantages of 3D printing technology are growing as it advances. The limits of what is feasible are being pushed by developments in materials science, printing speeds, and multi-material printing. In order to make 3D printing a practical choice for large-scale manufacturing, researchers are looking into new methods to incorporate technology into mass production.

We should anticipate even more industries utilizing additive manufacturing in the future. The capacity to produce intricate, highly customized items on demand will spur efficiency and creativity and open up new avenues for both consumers and enterprises.

Subscribe and Watch Our Latest Video

Don’t miss out on our latest video! Whether you’re a beginner looking to learn the basics or a professional seeking advanced tips, our videos are designed to provide valuable insights for everyone. Click here to subscribe and start exploring today.