Overview of Additive Manufacturing

Layer by layer, material is added throughout the additive manufacturing process to produce three-dimensional objects. AM constructs items from the ground up as opposed to conventional subtractive manufacturing techniques, which remove material from a larger block. Numerous materials, such as polymers, metals, ceramics, and even biological components, can be used in this procedure.

AM has advanced quickly, with notable improvements in speed, material diversity, and accuracy. As a result, it has been adopted by numerous industries, each of which is utilizing its special qualities to solve certain issues and optimize processes.

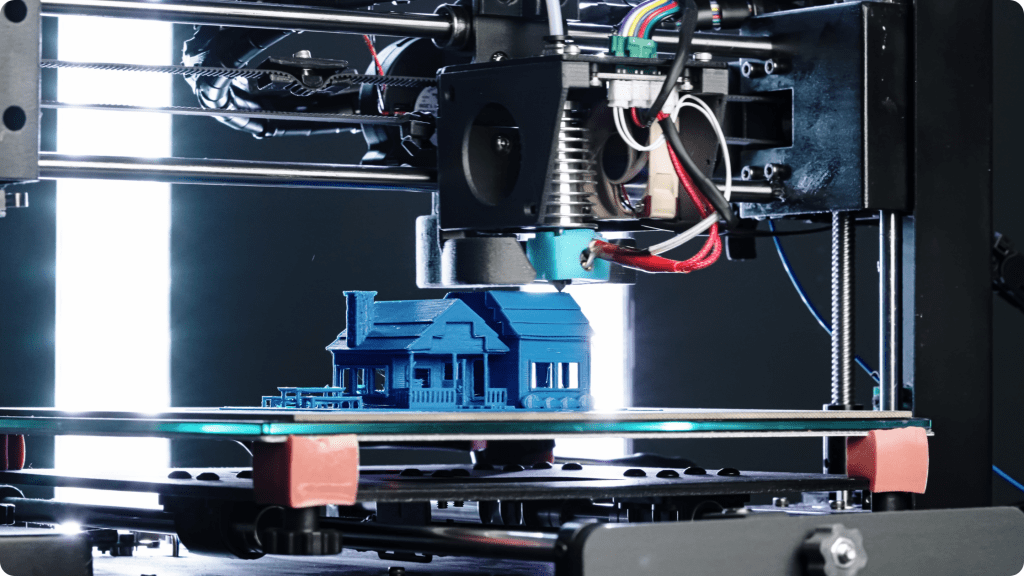

1. Complexity and Design Freedom

The freedom it provides for design is one of additive manufacturing’s biggest benefits. Because of the restrictions of tooling and material removal procedures, traditional production methods frequently impose limitations. On the other hand, AM makes it feasible to create elaborate designs and complicated geometries that would be unfeasible or prohibitively expensive to do using conventional techniques.

Complex Structures: AM makes it possible to build intricate internal structures that can save weight and material without sacrificing strength, like internal channels and lattice patterns.

2. Quick Development and Prototyping

Another important advantage of AM is its ability to generate prototypes quickly. Conventional prototype techniques can entail expensive setup times and protracted setup times. Prototypes may be made quickly with additive manufacturing, enabling more rapid iteration and improvement.

Reduced Time-to-Market: Businesses can gain a competitive edge by bringing items to market faster thanks to faster prototyping and testing.

Cost Efficiency: Better design optimization is made possible by the affordable production of multiple prototypes due to lower tooling and material costs.

Instant Feedback: Prototypes may be sent to designers and engineers for instant feedback, which enables more rapid changes and advancements.

3. Production Cost-Effectiveness

Even though additive manufacturing is frequently linked with greater prices for high-volume production, it can be more affordable for low to medium production runs, especially when taking into account the traditional manufacturing process’s setup and tooling expenses.

Decreased Tooling Costs: AM makes short production runs more affordable by doing away with the need for pricey molds and dies, which lowers upfront costs.

Material Efficiency: Compared to subtractive manufacturing techniques, the additive process minimizes waste by using only the material required to make the object.

On-Demand Production: AM makes it possible to produce goods as needed, which lowers the cost of inventory and eliminates the need for sizable warehouses.

4. Environmental Impact and Sustainability

In the manufacturing industry, sustainability is becoming more and more important, and additive manufacturing has many positive environmental effects.

Material Efficiency: By using only the material required to construct the object, AM’s layer-by-layer method minimizes wastage and extra material.Energy Efficiency: Compared to traditional production techniques, which can entail high temperatures and substantial machinery, additive manufacturing (AM) processes often use less energy.Recycling and Reuse: Utilizing recycled materials is encouraged by certain AM technologies, which increases the production process’s sustainability.

5. Individualization and Tailoring

Products that are individualized and customized are expertly produced via additive manufacturing. This potential is revolutionizing sectors such as healthcare, where prosthetics and customized medical equipment are becoming increasingly widespread.

Medical Devices: By customizing implants, prosthetics, and dental devices to each patient’s unique anatomy, fit and functioning can be enhanced.

Consumer goods: It is simple to make customized goods that meet the unique tastes and preferences of customers, such as personalized accessories or footwear that fits perfectly.

Small-Batch Production: AM is perfect for creating customized or limited-edition goods in small quantities, providing distinctive solutions that make a statement in the marketplace.

6. Less Complexity in the Supply Chain

Because additive manufacturing allows for local production and lessens the need for intricate logistics, it can simplify supply chains.Localized Production: Additive Manufacturing (AM) lowers lead times and transportation costs by producing goods and parts near their point of use.

Decreased Inventory: Large stockpiles are not necessary with on-demand manufacture, which lowers storage costs and the chance of obsolescence.

Faster Response Times: By reducing the impact of supply chain interruptions, localized production allows for speedier responses to changes in demand.

7. Increased Adaptability in Manufacturing

Another important advantage of AM is its ability to provide flexibility in manufacturing processes. Without requiring significant process modifications or retooling, the technology can adjust to different production demands.Versatility is appropriate for a variety of applications since it can operate with a broad range of materials and adjust to differing product requirements.Adaptable Production: Modifications to design or production specifications can be swiftly adopted without requiring the reconfiguration of production lines or the purchase of new tools.Quick Iteration: The flexibility to alter a design quickly enables ongoing enhancement and adjustment to changing market demands.

8. Enhanced Quality and Performance

By providing more exact control over the manufacturing process and material parameters, additive manufacturing can improve product performance and quality.High-resolution 3D printing can produce parts with intricate details and tight tolerances, leading to improved quality and performance. for the creation of parts with optimized material properties, such as enhanced strength, flexibility, or thermal resistance.The ability to print complex geometries and structures can reduce the likelihood of defects and failures, leading to higher-quality end products.

9. Inventiveness and Novel Business Frameworks

Opportunities for innovation and new business models that were previously unreachable with traditional production methods are made possible by additive manufacturing.

New Product Development: By enabling the investigation of novel product concepts and business strategies, additive manufacturing (AM) contributes to innovation and uniqueness.

Collaborative Design: To enable more integrated and effective product development processes, AM promotes collaboration between designers, engineers, and manufacturers.

Crowdsourcing and Customization: Companies can improve engagement and market appeal by creating personalized goods and services via the use of crowdsourcing and consumer input.

Subscribe to Our YouTube Channel: Get access to our full library of videos and stay updated with the latest content.

Discover the future of manufacturing with our latest video, where we delve deep into the transformative world of additive manufacturing. Our video provides an insightful overview of how 3D printing is revolutionizing industries, from automotive and aerospace to healthcare and consumer products. You’ll gain a comprehensive understanding of the latest advancements, applications, and benefits of this cutting-edge technology.

Advantages.

Businesses may successfully navigate the changing terrain of contemporary production and realize the full potential of this game-changing technology by comprehending and utilizing the advantages of additive manufacturing.